Marketing policy message: you must update this message in the Shared Zone called 'Privacy Policy and Marketing Communications.

Eox Check Valves- Discover our wide range of check valves and find out more about each of our ranges.

Because of their simple design, check valves generally operate without automation or human interaction and instead rely on the flow velocity (upstream pressure) of the liquid or gas to open and close. This means they generally do not have a method of external operation, like a handle or lever. The minimum upstream pressure required to open the valve is called the “cracking pressure”. Check valves are designed for a specific cracking pressure.

Eox offers check valves which are available in various specification and material options. Valve types include: Modular, Duckbill, Floating Disc, Diaphragm, Poppets, Umbrella and Cartridges.

Check valves are also known as non-return or one-way valves, and are often used as pressure relief valves. The basic design of a check valve inhibits backflow and allows the flow of either liquid or gas one way

Our strength lies in our ability to support customers who are supplying into the medical and scientific markets. We provide many specification and material options specifically designed to meet the standards and compliances required by the healthcare industry

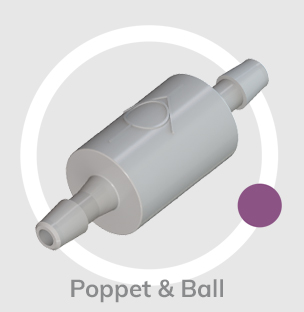

Poppet/Ball Check Valves - Positive sealing, low pressures

It is important to note that the poppet style check valve is usually designed to be normally closed. Poppet type valves generally utilise a spring to force shut the orifice by holding a component against a seal to replicate the backflow pressure. Spherical shapes like ball bearings with smooth surfaces, which seal against an O-ring seal, or poppets, which generally incorporate an O-ring seal and seal against a smooth face. Visit our Poppet & Ball range.Key features include:

- Provides quick interruption of flow- Provides positive sealing at pressures below the cracking pressure of the valve

- Does not require gravity or backflow pressure to work or actuate

- Provides positive valve closure regardless of vertical orientation

- Prevents system fluid or gas backflow during routine maintenance

Floating Disc/Diaphragm - Cost effective

Floating disc check valves use a self-centring flexible elastomer disc. The valve body keeps the disc centred over the sealing surface of the valve. Diaphragm check valves are almost always normally closed. Diaphragm design types typically rely upon a formed membrane shape fixed in position and sealing against the inlet surface through the spring force of the membrane. Visit our Floating Disc range.

Key features include:

- Positive seal

- Orientation dependant

- Variable opening pressure through seat thickness

- Cost effective

- Corrosion resistant

- Wear resistant

- ISO 80369 - 7 compliant check valves available

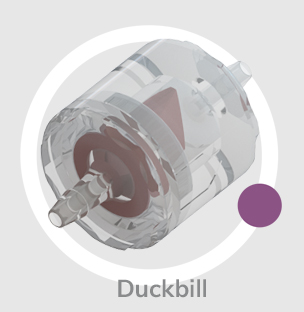

Duckbill Check Valves - Low opening pressure

Duckbill valves are unique, one-piece, elastomeric components that act as backflow prevention devices, one-way valves or check valves. They have elastomeric lips in the shape of a duckbill which prevent backflow and allow forward flow. Visit our duckbill range.

Key features include:

- Position independent

- Low opening pressure- immediate free flow

- Non-tortuous flow path

- High flow rate vs. package size

- Virtually no internal volume and dead space

- Particle compliant

- Corrosion resistant

- Wear resistant

- Cost effective

Umbrella Check Valves - Immediate positive seal

Umbrella valves are elastomeric valve components that have a diaphragm shaped sealing disc or an umbrella shape. These elastomeric components are used as sealing elements in backflow prevention devices(one-way valves or check valves) in (vent valves or pressure relief valves) and in metering valves. Visit our Umbrella range.

Key features include:

- Immediate positive seal

- Position independent

- Variable opening pressure through seat thickness

- High flow rate vs. package size

- Corrosion resistant

- Wear resistant

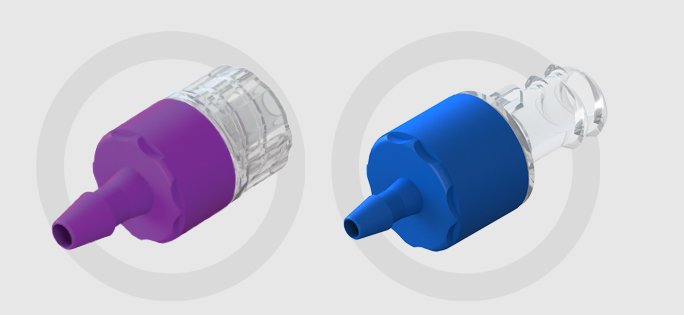

View our range of ISO 80369-7 Check Valves

These check valves are designed to improve patient safety by reducing the risk of mis-connections with small-bore connectors which are used in liquid and gas healthcare applications

Eox Check Valve Book

At Eox we understand one size doesn’t fit all and have created our latest catalogue to help you find exactly what you need for your project or application. Click here to download the Eox Check Valve book

To help with your selection we’ve included:

- Detailed product data for individual components including pricing

- 1:1 images – representing actual component size

- Dimensional drawings to help with your design process

- A technical overview for each type of check valve

Modular Check Valves

Our new addition to the range is modular check valves. These utilise a spring-forced floating poppet which will allow flow at a cracking pressure to suit you, with many configurations. These check valves have many attributes:

- Compatible with clean air

- Modular assembly allows multiple combinations

- Single barb design improves seal and clamping

- Female thread form options for 1/8" NPT, BSPT and BSPP fittings

- Locking clip to prevent accidental disassembly

- Easy to use cartridge for manifold assembly

- Mixed imperial and metric combinations

- Multiple spring options

Click here to configure your check valve